Choosing Adhesive

Introduction

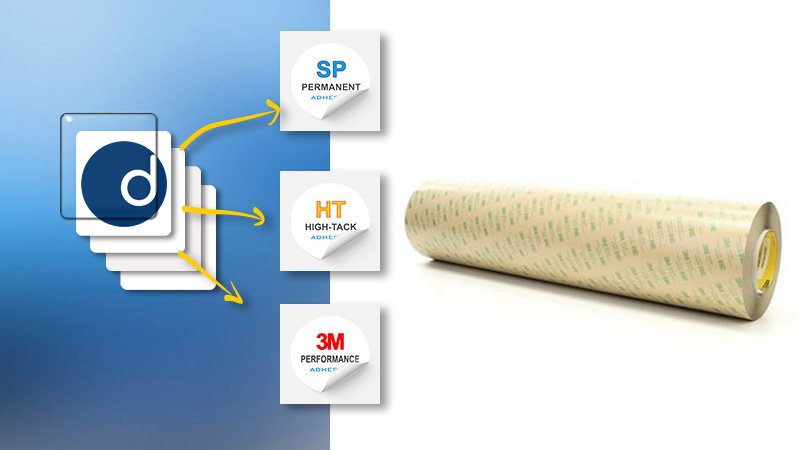

Why need different adhesive layers?

We offer the option to choose a different adhesive layers in order to cover as much as possible of customer requirements. Although each of the tree adhesive types has good adhesion properties and resistance, they are different in details.

FTM 2

FINAT is the European association for the self-adhesive label industry.

FINAT Test Method 2 – Peel adhesion (90°) at 300mm per minute. Test method to quantify the performance of adhesion or peelability of self-adhesive (pressure sensitive) materials.

SP Standard Permanent Adhesive

Standard Permanent Adhesive is an acrylic dispersion with excellent clarity, UV-stability and water resistance with limited adhesion at low temperatures and on corrugated surfaces.

Area of use

Standard Permanent adhesive type covers almost 95% of application areas. After doming stickers are applied, the process of adhesion will continue over time and actually the adhesion strength will increase over years. Doming stickers with Standard Permanent adhesive are suitable for use on flat and smooth surfaces. The most common applications are for branding household appliances, electronics, sports equipment, POS displays, business cards, custom packaging, keyholders and many more…

Technical Data

| Thickness | 35 microns |

| Adhesion FINAT TM 2 on stainless steel | 12,5 N/25 mm after 24 hr at 23° C |

| Temperature resistance | - 10° C to +100° C |

| Resistance to solvents and chemicals | With expert application resistant to most oils and greases, fuels, aliphatic solvents, weak acids, salts and alkalis |

| Application temperature | > +15° C |

| Manufacturer | UPM Raflatac Europe |

3M High Performance 200MP

3M™ High Performance Acrylic Adhesive 200MP is a popular choice for general industrial and commercial applications. It provides outstanding adhesion to metal and high surface energy plastics. It also performs well after exposure to humidity and hot/cold cycles.

Area of use

Doming stickers with 3M™ High Performance Adhesive are recommended option when mounting surface is curved /not less than 30 cm in diameter / or slightly textured.

Technical Data

| Thickness | 60 or 130 microns |

| Adhesion FINAT TM 2 on stainless steel | 60 microns - 25 N/25 mm after 72 hr at 23° C 130 microns - 30 N/25 mm after 72 hr at 23° C |

| Temperature resistance | - 40° C to +149° C, for short periods up to +200° C |

| Resistance to solvents and chemicals | With expert application resistant to most oils and greases, fuels, aliphatic solvents, weak acids, salts and alkalis |

| Application temperature | > +15.6° C |

| Manufacturer | 3M Industrial Adhesives and Tapes Division - USA |

General recommendations table depending on mounting surface

High Surface Energy Metals

| Metal | Surface Energy Dynes/cm |

| Copper | 1103 |

| Aluminum | 840 |

| Zinc | 753 |

| Tin | 526 |

| Stainless Steel | 700-1100 |

High Surface Energy Plastics

| Plastic | Surface Energy Dynes/cm |

| Phenolic | 47 |

| Nylon | 46 |

| AlkydEnamel | 45 |

| Polyester | 43 |

| EpoxyPaint | 43 |

| Polyurethane | 43 |

| ABS | 42 |

| Polycarbonate | 42 |

| PVC Rigid | 39 |

| Acrylic | 38 |

Low Surface Energy Plastics

| Plastic | Surface Energy Dynes/cm |

| PVA | 37 |

| Polystyrene | 36 |

| Acetal | 36 |

| EVA | 33 |

| Polyethylene | 31 |

| Polypropylene | 29 |

| Polyvinyl Fluoride Film | 28 |

| PTFE Fluoropolymer | 18 |

| Powder Coatings | Broad range |

Test Recommended!

Test Recommended!

For application on LSE Plastics it is highly recommended to use 3M™ Adhesive 300LSE – aviable on request.

Contact us for more details.

Conclusion

From our experience through the years, we can say that Doming stickers with Standard permanent adhesive will meet a huge range of applications both for indoor or outdoor use.

Because it’s hard to test the adhesion of stickers on all possible surfaces, it’s highly recommended requesting a Free Sample pack before placing an order especially when doming stickers should be applied on surfaces or in conditions out of the ordinary use.